Oysters: From Shell to Shucked

Author: Tripp Smith, Virginia Certified Ecotour Guide

A Brief History

In 1897 my great grandfather started an oyster business in the little village of Sharps. Sharps is located about 20 miles up the Rappahannock River from the Chesapeake Bay. Like many towns in that era the steamboat played an important role in the economy. This oyster plant was located on a steamboat wharf along with several other business. It operated at that location until 1954 when Hurricane Hazel wiped out the plant. What do you do? You buy a piece of land close to the water and start again. That’s what my Grandfather did. It was an island, mainly of sand and marsh. He built a bulkhead around most of it and filled it in with oyster shells and dirt. Fast forward 67 years and most of it is still there, although it has changed shape with erosion and redistribution of sand on the river side, it is no longer an island. The bridge to access it still standing strong. Last time we had it surveyed they said you could drive a freight train across it. Keep in mind it was built with creosote treated lumber. We are no longer in this industry due to the collapse of the oyster industry in the early 90s along with ¾ of the buildings being destroyed by fire at about the same time. With what is left I hope I can give you a sense of what it was like to be in this industry when it was booming.

In 1897 my great grandfather started an oyster business in the little village of Sharps. Sharps is located about 20 miles up the Rappahannock River from the Chesapeake Bay. Like many towns in that era the steamboat played an important role in the economy. This oyster plant was located on a steamboat wharf along with several other business. It operated at that location until 1954 when Hurricane Hazel wiped out the plant. What do you do? You buy a piece of land close to the water and start again. That’s what my Grandfather did. It was an island, mainly of sand and marsh. He built a bulkhead around most of it and filled it in with oyster shells and dirt. Fast forward 67 years and most of it is still there, although it has changed shape with erosion and redistribution of sand on the river side, it is no longer an island. The bridge to access it still standing strong. Last time we had it surveyed they said you could drive a freight train across it. Keep in mind it was built with creosote treated lumber. We are no longer in this industry due to the collapse of the oyster industry in the early 90s along with ¾ of the buildings being destroyed by fire at about the same time. With what is left I hope I can give you a sense of what it was like to be in this industry when it was booming.

Harvesting: Tongs & Dredging

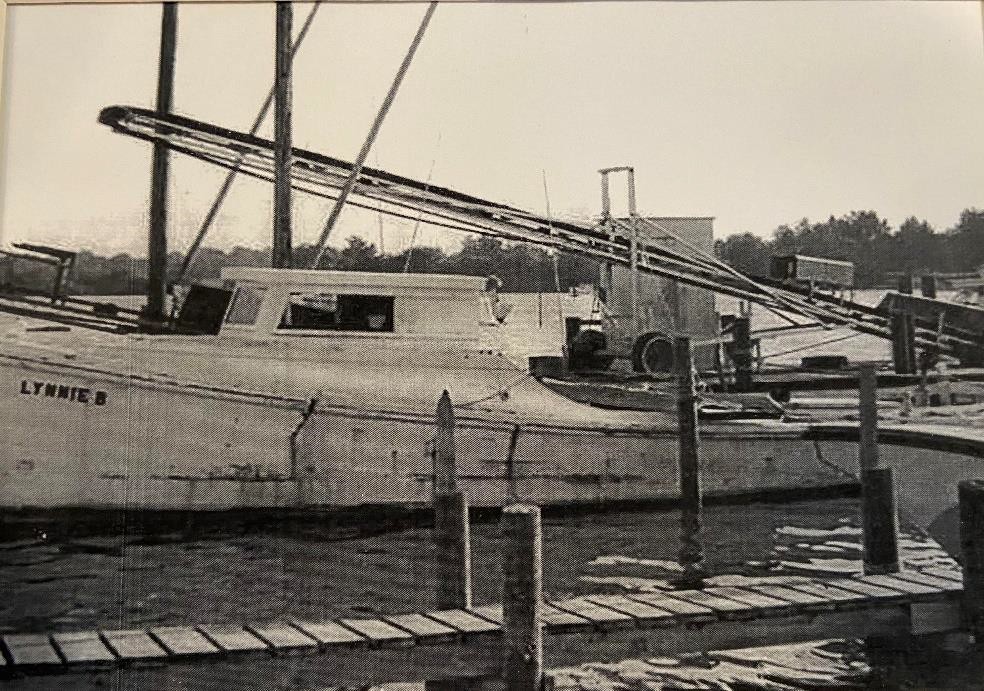

The first method used in harvesting of oysters are tongs. On the private grounds this is what I remember seeing the most. This way was done from a deadrise with wide wash boards to provide sturdy footing. On Morattico creek, in the hay day of oysters, there could be as many as 20 deadrises anchored in the creek.

Round stern and box stern were the two most prevalent styles. Most had some sort of small forward cabin and all had an engine above deck so there could be a lower freeboard. Having a lower freeboard meant it was easier to bring oysters over the side to the culling boar while also lowering the center of gravity. Due to higher maintenance, there are not as many deadrises working the oyster grounds. As time has progressed you see more flat-bottomed fiberglass skiffs with outboard motors. Oysters were brought up and put on a culling board that ran perpendicular to the boat and stretched from port to starboard usually right behind the small forward cabin. Usually there were two men tonging and one culling.

The second method is dredging. This is more mechanical and takes less physical stamina. This method can be argued is better for the oyster ground because it turns over the oysters freeing them from the silt that has built up over time.

However, if not done in the correct form could also destroy a bed by digging to deep (show picture). Weather depending, most boats would get to the grounds around first light and arrive back to the dock around noon.

Ideally at this point we would go out on a deadrise with tongs or dredges and harvest oysters, giving them a sense of what it’s like.

Unload on Dock

Unloading from boat to pier is done by shoveling the oysters into bushel tubs. Those tubs are then hoisted by a mechanical pulley system and dumped onto a conveyor that runs upward to the roof where there is a hole for them to fall through to the shell stock room. The tongers or dredgers were paid by the bushel so each bushel was counted per boat. A common technique tongers and dredgers used was to “cup” the tub, which means to put the oysters on the outer portions of the tub and leave the middle somewhat hollow. This would allow for them to have a higher bushel count per boat, but was frowned upon from the buyers because they weren’t getting a true bushel. After unloading each boat would tie up to a pole out in the creek and use a small john boat to get back to shore.

Shell Stock Room

The shell stock room is where the shell oysters were stored before being processed. This room is held at about 40F. Keep in mind that the oysters are still alive at this point and don’t die until they are shucked. They can stay in the shell stock room for up to a week?

There is a very distinct aroma to this room. Some would say it is a bad aroma, but it you’re in this industry is just smells like money.

Packaged

Shell oysters were shucked by the gallon or boxed in the shell by the bushel or half bushel. If boxed by the bushel they were run under jets of water to be remove the mud and the muscles and sea squirts had to removed by hand. Then they were sorted into Standards and Selects and boxed.

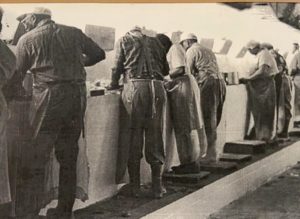

If not boxed for sale by the bushel they were shucked to be sold by the gallon. Some would argue that shucking oysters is an art. Since they are paid by the pound the faster you are, the more you make. There were times when they knew that the oysters in the shell stock room were small so not all of your work force would show until bigger oysters came along. A shuckers tools are a shucking knife, apron, a wedge, white boots and rubber gloves.

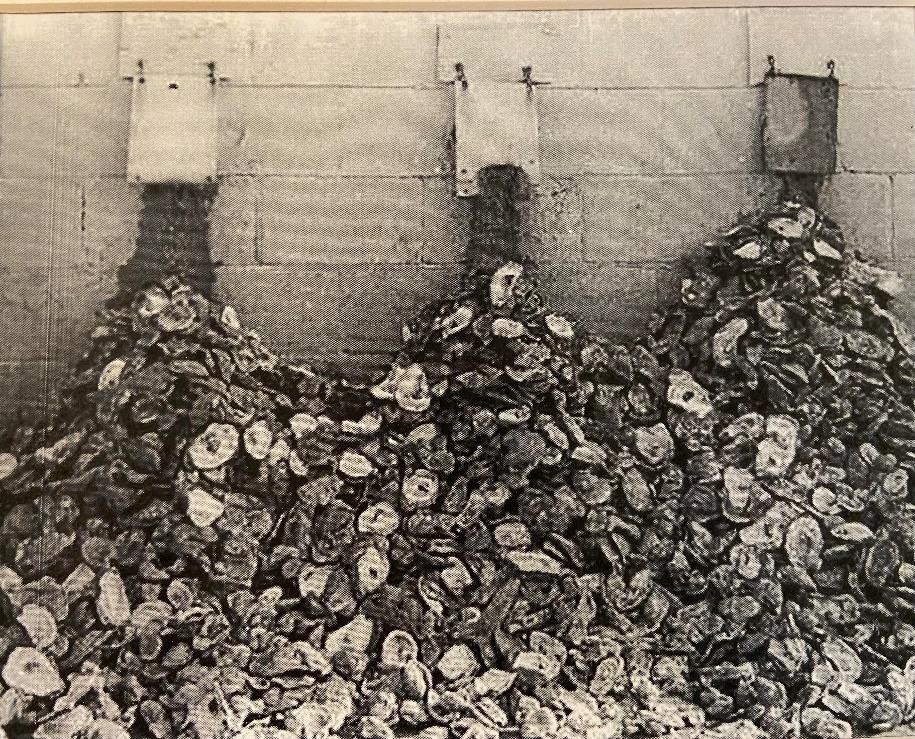

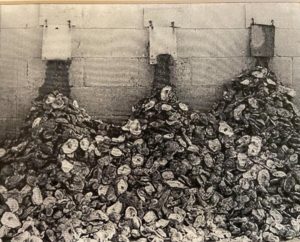

The wedge was used to get a better angle to penetrate the lip of the oyster. After shucking they were put into a stainless-steel pail and once that was full, they would take it to be weighed. The shell was sent through a shoot in the wall to the outside of the building where a tractor would scoop them up and put them in a pile to be planted at a later date. Our shucking room could house about 40 shuckers.  They ranged in age from 20 to 70 male and female and sometimes a husband and wife. There day started around 3am and ended anywhere from 11 to 1.

They ranged in age from 20 to 70 male and female and sometimes a husband and wife. There day started around 3am and ended anywhere from 11 to 1.

The photos can give you a pretty good idea of how things looked, but I think what sticks out most are the sounds and smells that are associated with it. For instance, on the outside of the shucking wall you will notice a metal plate hanging in front of the opening. As that oyster shell is sent  down that shoot the shell hits the metal plate. The shell makes that plate move back and forth knocking up against the concrete wall. Imagine 30 shuckers sending shells down those shoots at random intervals. Combine the sound of the shell hitting the metal plat and the plate bouncing off the wall it created a constant wind chime effect. Even when not shucking the wind would frequently move those plates back and forth creating the same effect.

down that shoot the shell hits the metal plate. The shell makes that plate move back and forth knocking up against the concrete wall. Imagine 30 shuckers sending shells down those shoots at random intervals. Combine the sound of the shell hitting the metal plat and the plate bouncing off the wall it created a constant wind chime effect. Even when not shucking the wind would frequently move those plates back and forth creating the same effect.

Packing Room

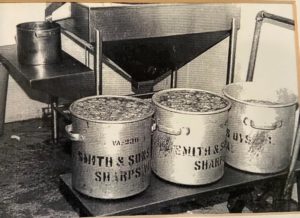

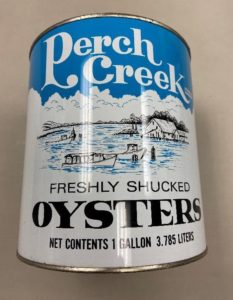

At this stage they are separated into mainly standards and selects. Standards are the smaller and selects are the bigger. After separated they are put into blower tanks to be washed and sanitized. They sit in these tanks to soak up water. Then they are dumped over a skimmer (visualize a big colander) and put into gallon containers. I’m not sure of the year but they use to be put into containers that were aluminum and each can had your brand on it.

At this stage they are separated into mainly standards and selects. Standards are the smaller and selects are the bigger. After separated they are put into blower tanks to be washed and sanitized. They sit in these tanks to soak up water. Then they are dumped over a skimmer (visualize a big colander) and put into gallon containers. I’m not sure of the year but they use to be put into containers that were aluminum and each can had your brand on it.  These aluminum cans are now highly sought after and can bring $100 per can, where they use to cost pennies. Now everything is in plastic . After being put into containers then they are put into waxed boxes and iced down then put into a cooler. During peak season there could be a thousand gallons or more stored in the cooler waiting to be shipped.

These aluminum cans are now highly sought after and can bring $100 per can, where they use to cost pennies. Now everything is in plastic . After being put into containers then they are put into waxed boxes and iced down then put into a cooler. During peak season there could be a thousand gallons or more stored in the cooler waiting to be shipped.

Shell planting

In the spring and summer, the shells were loaded onto a barge and redistributed back to the oyster grounds to provide a place for young oysters to attach and grow.

Although we aren’t using the existing building there are two different aquaculture businesses operating out of that location. They are utilizing the pier and some of the cement slab to run their operation. It’s comforting to know that a small piece of this location is being used as it was originally intended for. From an ecotourism perspective having a healthy population of oyster, either farm or wild grown helps keep the Bay and rivers clean by filtering up to 50 gallons of water per day. I hope to tie this into the aquaculture business by combining my efforts with Awesome Oysters who utilizes this property to run his operation.